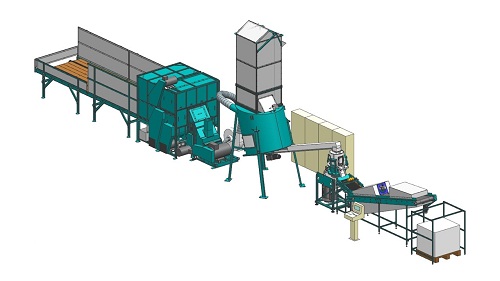

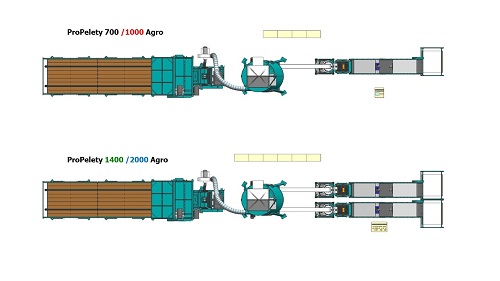

Pellet production line ProPelety Agro Basic / Power / Basic Duo / Power Duo

Pellet production line for hay or straw.

Pellet production line for hay or straw.

Input material shape is cylindrical bales of maximum 150 cm in diameter, or square bales of max.150x150 cm cross section. Loose or bulk material can also be used. Maximum humidity of material can be up to 14 %. In case of higher humidity, the production line has to be equipped with a drying section. In basic arrangement of the production line pellets are packed in big volumes – i.e. in big-bags or containers (or optionally loose). Operation of all parts of the line is continuous. All the production line is controlled from one main panel. It is designed to be operated by a single worker, who is also responsible for material handling – bale feeding, replacing big-bags, etc.

Production line can be modified for specified purpose and with regards to material used